MATERIAL

MATERIAL

The visual and haptic identity of a textile product is controlled by the choice of the fabric. So the selection of the right fabric is one of the most important design actions. We cooperate with several suppliers of fabrics, meshes and foams which have quite a few interesting solutions.

We can choose out of a variety of textures, coatings, weights and of course price in Polyester, Polyamide (Nylon), Hypalon, Cotton, Leather, …

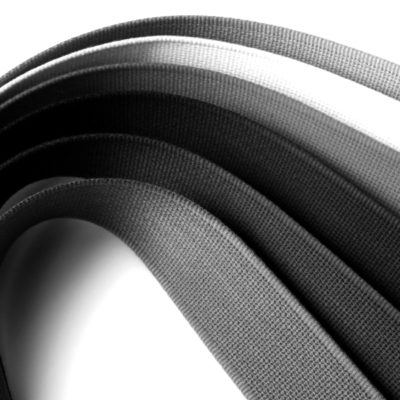

We are very well experienced in webbing development and work together with different weaving mills and test institutes to provide the solution which fits your requirements the best. If it doesn’t need to be a customized webbing, there is plenty of standard and innovative solutions from product catalogues of several suppliers we can choose depending on the requirements.

Especially for textile load bearing components (webbing, cord) its important to choose a raw material with the characteristics (tensile strength, elasticity, abrasion resistance, water absorption) which fit the later application best. The most experience I have made with synthetic fibers made of Polyamide (PA 6 and PA 6.6), Polyester, Polypropylene and Dyneema® (UHMWPE). For all other applications with regular requirements there is a variety of natural fibers which are preferable regarding sustainability issues.

Details make the difference. Therefore also the trims should be carefully selected, whether its zippers, buckles, cord ends, zipper pullers, … No matter if you choose out of a catalogue or if you want to have an own design – the cooperating partners are willing to satisfy all your wishes. Also prints, embossings or embroideries should be well chosen and usually need some try-outs before they can be approved. We can support in all these matters with a lot of experience from previous projects and the cooperation with important trim suppliers like YKK, Duraflex, Nifco, NILORN and more.

To provide light solutions for functional trims + buckles and to have a wide variety of colors it is usually the best solution to choose plastic. The selected type of plastics is depending on the requirement of the later usage and also the manufacturing process. The range goes from ABS, Nylon, POM, Hytrel to TPU and TPE. For specific solutions it makes sense to overmold webbing with plastics. Our experience and our network allow me to offer full design and development support for your customized issues. This includes the advancing additive manufacturing (3D printing, Laser Sintering, …) which mean a great potential for customized designs.

Choose metal for load bearing and rather stressed connections and buckles. Metal may also be used to generate a more durable and premium look – steel for the reliable or classy appearance and aluminium for lightweight or technical esthetics.

Besides the parts which are offered by the suppliers catalogues there is also the option to make customized parts or to customize parts by adding a logo by stamping or even laser engraving. And of course new additive manufacturing processes (e.g. laser sintering or laser melting) allow also for metal solutions a whole lot new design options.